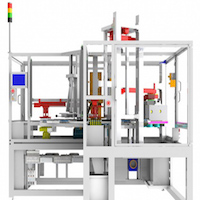

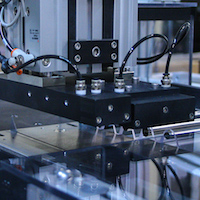

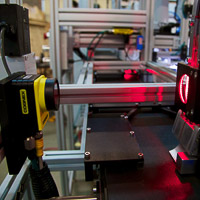

Design

We have a proven track record of solving difficult problems with innovative design concepts. Our engineers are highly experienced in a variety of projects from manual assembly stations to complex robotic systems. We hold a series of design reviews or work independently depending on our customers' preference.