Automatic Pin Inserter

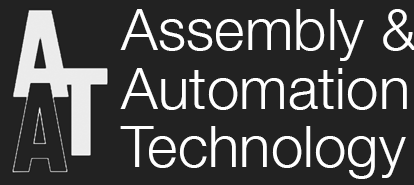

PI-M, PI-700 & PI-1400

Pin Inserters

Cut assembly costs and increase production rates with Assembly and Automation Technology's Automatic Pin Inserters. Our Pin Inserter line offers superior part handling and insertion performance for automatic production systems and single work stations.

Contact Us

PRECISION

- Increase Productivity up to 6 times over manual methods

- Part gauging features for both the cross section and for long parts

- Hardened tooling for long life

- Programmable Logic Controller (PLC) for reliability

- Precision-ground cast iron base with bench-top mounting

- Precise repeatable stroke within 0.01 inch

- Retracting head for easy part loan and unload

- Infinite stroke adjustment within range

- Non-rotating ram

- Filter/regulator/lubricator (FRL) with pressure gauge

- Custom slide/nest available

| Model PI-M | Model PI-700 | Model PI-1400 | |

|---|---|---|---|

| Pin Cross Section Length (inches) | .062-.250 | .062-.250 | .062-.250 |

| Pin Length (inches) | .250-1.250 | .250-1.250 | .250-1.250 |

| Press Force @ 100 PSI | 350 | 700 | 1400 |

| Adjustable Stroke (inches) | 2-3 | 2-3 | 2-3 |

| Throat Depth (inches) | 4.5 | 4.5 | 4.5 |

| Maximum Shut Height (inches) | 7.0 | 7.0 | 7.0 |

| Maximum Cycle Rate (parts/min) | N/A | 40 | 40 |

| Tooling Holes in Base | (2) 5/16-18x5 | (2) 5/16-18x5 | (2) 5/16-18x5 |

| Electrical Requirements (Volts/Hz) | 115/60 | 115/60 | 115/60 |

| Pneumatic Requirements (PSI) | 30-100 | 30-100 | 30-100 |

| Weight (lb.) | 112 | 125 | 129 |

| Model PI-M | Model PI-700 | Model PI-1400 |

|---|---|---|

|  |  |

| The manual arbor allows for tactile sensing while inserting. Hand lever mounts to a splined shaft to allow for handle location adjustment. Part gauging included for long parts. Increases productivity up to 6 times over completely manual methods. | Low force (1 oz.) dual palm non-tie down/non-repeat pneumatic safety actuators. The PI-700 is adaptable to fully automatic rotary, linear and x-y systems. Includes double acting cylinder and flow control for stroke velocity adjustment. | Features of PI-700 with greater press force capability for larger pins and tighter press tolerances. Maximum press force of 1400 lb. A second column may be added for higher forces/longer shut heights. |

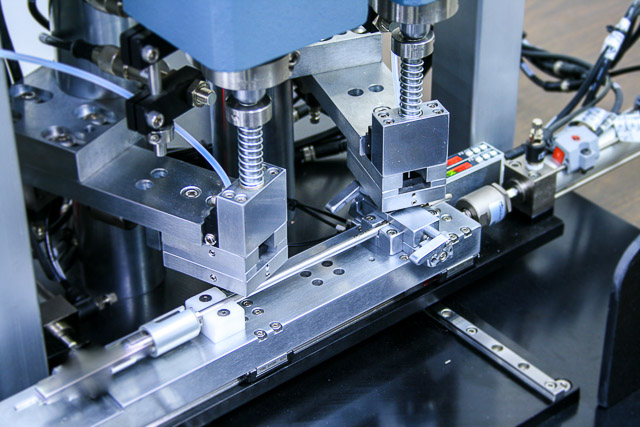

Automatic Pin Inserter Operation

Pins are loaded into a vibratory feeder bowl. The vibratory feeder bowl orients pins automatically and feeds them into a tube. The pin inserter escapes one pin and inserts into the part.

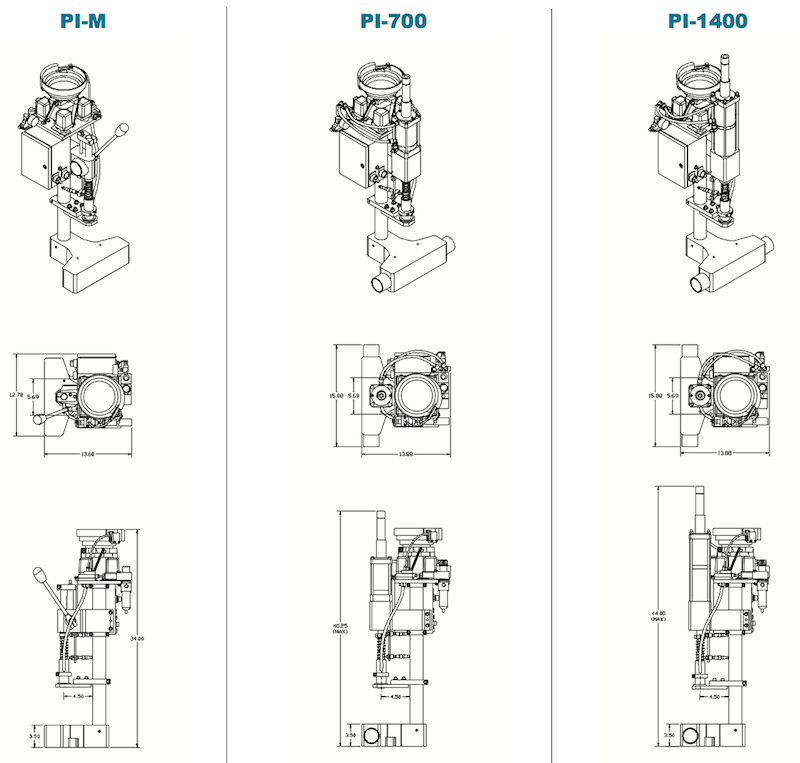

Fully Customizable

Systems can be custom designed with single or multiple pin insertion heads to reduce labor costs, increase productivity and improve quality. Semi and fully automated machines and production lines can incorporate other assembly functions and provide inspection systems to complete your manufacturing requirements. For an example of an automatic system please see Automatic Pin Inserter Systems in custom equipment.

Technical Support

Assembly & Automation Technology will utilize its decades of experience to provide sample part evaluation, application engineering assistance, and custom tooling design.