Automatic Screwdriver

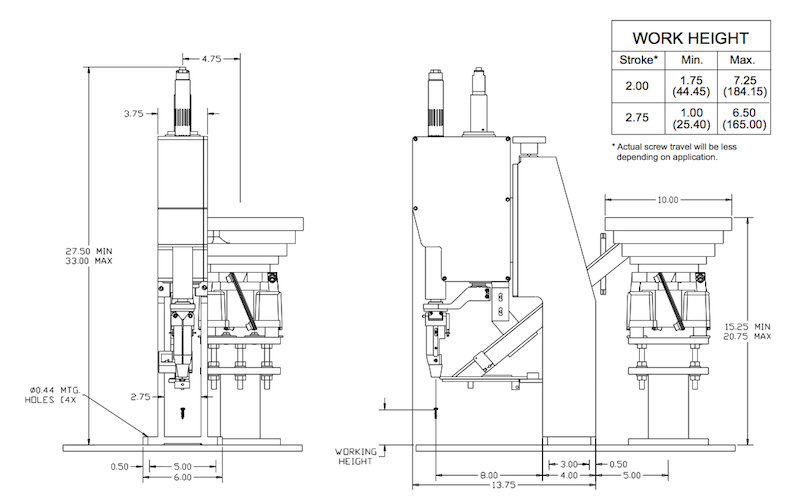

S-250 Automatic Screwdriver

Cut assembly costs and increase production rates with Assembly and Automation Technology's S-250 Automatic Screwdriver. The S-250 offers superior fastening performance for automatic production systems and single work stations. Also available in N-250 Nutdriver configuration.

Contact Us

PRECISION

- Positive screw placement

- Consistent torque depth control

- Regulated speed of the drive head

- Full track sensing shuts off the feeder bowl

COST EFFECTIVE

- Minimum set up time; easy to adjust

- Choice of clutch or direct drive

- Jaw inserts reduce expensive chuck replacements

- Uses standard driver bits

- Drive motor only operates while screw ids being driven

- Easily retooled for product changes

RELIABLE PERFORMANCE

- Automatic screw feed and escapement system eliminates jamming of screws

- Automatic operation features instant stop control if part is missing or improperly driven

- Ejection of defective parts is available for automatic systems

- Low maintenance; all mechanisms are easily accessible

- Cast aluminum frame and hardened steel tooling

BUILT-IN VERSATILITY

- Choice of 6 RPM speeds with 6 torque ranges

- Simple adjustments to change from torque control to depth control

- Ejection of defective parts is available for automatic systems

- Mechanism to delay closing of chuck during the return stroke

| Power: | Air: 90 PSI (6.327 kg/cm2) 2-5cfm 0.944-2.360 liters/sec) |

| Controls: | Electric with programmable controller equipped with dual palm switches or foot switch. Controls for automatic operation available |

| Torque: | Six (6) adjustable torque ranges from 5-86 in-lb. (0.6-9.7 Nm) |

| Motor Speed: | Choices of six motor speeds from 650-3000 RPM |

| Assembly Rate: | Up to 60 cycles per minute dependent on screw type and length |

| Screw Size: | Headed screws #3 to 1/4 in. (2mm-6mm) |

| Feeder Bowl: | 10 in. (25.4 cm) dia. standard; other seizes and styles available |

| Weight: | Approximately 150 lb. (68 kg) including mounting plate and feeder bowl |

Automatic Screwdriver Operation

Screws are loaded into a vibratory feeder bowl. The vibratory feeder bowl orients screws automatically and feeds them into a decline track. One screw is escaped at the base of the track and the inserting shuttle load it into the chuck jaws. The drive bit advances, turns, and falls into the screw slot shutting off the drive motor. The driving unit, chuck and screw descend toward the work piece. The screw contacts the work piece and the resulting pressure against the bit starts the drive motor. The screw is driven as the driving unit cams open the chuck jaws to clear the screw head. When the desired screw torque or depth is reached, the drive motor automatically shuts off. The S-250 resets to the start position for the next cycle.

Fully Customizable

Systems can be custom designed with single or multiple screw/nut drivers to reduce labor costs, increase productivity and improve quality. Semi and fully automated machines and production lines can incorporate other assembly functions and provide inspection systems to complete your manufacturing requirements. For an example of an automatic system please see Automatic Screwdriver Systems in custom equipment.

Technical Support

Assembly & Automation Technology will utilize its decades of experience to provide sample part evaluation, application engineering assistance, and custom tooling design.