Robot Systems

Robotic Efficiency & Flexibility

We utilize robotics in many of our systems to maximize speed and accuracy. Robots are ideal for the most demanding and complex production requirements. Our engineers are experts in integrating robots into automated assembly systems.

Start a Project With Us

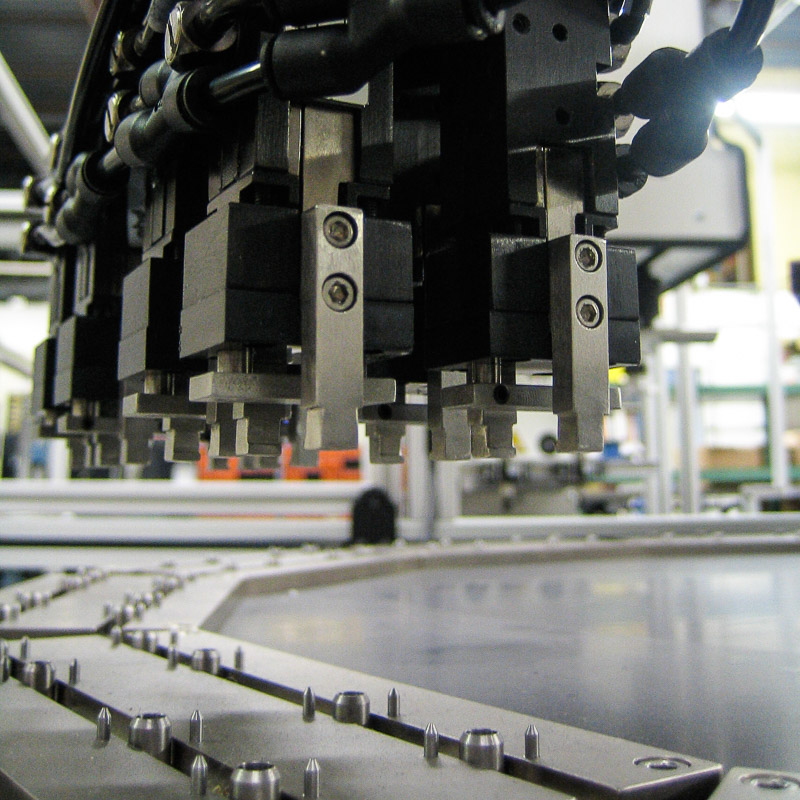

Medical Switch Assembly System

Bottom parts are loaded by vibratory feeder bowl down vibratory tracks and into custom indexing conveyors. Parts are picked up and loaded 8-up onto a rotary dial. Top parts are loaded in a similar manner and assembled onto the bottom parts. The parts are ultrasonically welded and printed with an indicator. A vision inspection system qualifies proper assembly and printed image. Good parts are offloaded to an eject bin and failed parts are offloaded to a reject bin.

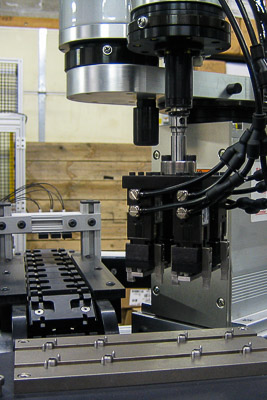

2-Up Robotic Adhesive Dispensing System

Fixtures are loaded and unloaded in a safe zone with front and back light curtains. The robot picks up fixtures pre-assembled with medical devices and inspects the parts for proper assembly. The robot manipulates the parts for servo-driven adhesive dispensing, curing and fluorescence inspection on three sides. On adhesive replacement, the dispensing needles are aligned using a laser sensor.